The Packaging Conundrum: Necessity Meets Responsibility

In the fast-paced world of grab-and-go meals, packaging is an unavoidable necessity . It protects food from contamination, preserves freshness, and provides a surface for branding and consumer information. However, the environmental impact of traditional food packaging, especially single-use plastics, has become a pressing global concern. This challenge has spurred a renaissance in material science, leading to the development of packaging that is not only functional but also environmentally responsible .

Beyond Plastic: Materials Revolutionizing Food Wraps

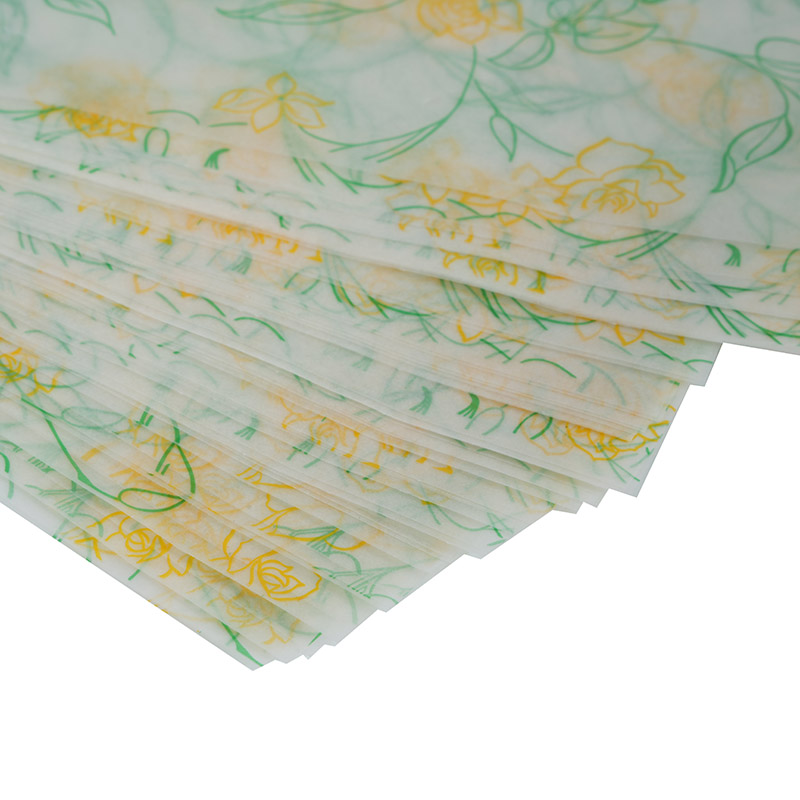

The core of the sustainable packaging movement lies in finding alternatives to conventional petroleum-based plastics. Several innovative materials are being adopted to create the next generation of food wraps, including the versatile Printed Sandwich Wrap .

Biodegradable Polymers

These materials, often derived from renewable sources like corn starch, sugarcane, or cellulose, are designed to break down naturally after disposal. Polymers such as Polylactic Acid (PLA) and Polyhydroxyalkanoates (PHAs) offer similar barrier and strength properties to plastic but decompose into non-toxic, natural components. The chemical structure of these polymers allows microorganisms to digest them under specific conditions, returning them to the Earth.

Waxed Paper and Sustainable Coatings

While paper is inherently more compostable than plastic, it often lacks the grease and moisture resistance needed for food like sandwiches. Innovations in sustainable coatings are addressing this. Instead of paraffin wax (a petroleum product), wraps are now often coated with beeswax , soy wax , or food-grade mineral oils . These natural coatings create an effective barrier while ensuring the final product—including the Printed Sandwich Wrap —remains recyclable or home-compostable.

Aluminum Foil and its Recyclability

Aluminum foil, while resource-intensive to produce, is infinitely recyclable . Its excellent barrier properties against light, moisture, and oxygen make it ideal for maintaining food quality. The focus here is on increasing the collection and recycling rate to maximize its sustainability benefits.

The Technology of Print: More Than Just Ink on Paper

The “Printed” aspect of Printed Sandwich Wrap is a critical area of innovation, extending far beyond simple branding to include advanced functionality and safety.

Food-Grade and Non-Toxic Inks

Safety is paramount. Modern food packaging inks are rigorously tested to ensure they are non-toxic and do not migrate into the food. Vegetable-based inks, derived from sources like soy or linseed, are often preferred over traditional solvent-based inks. These inks are safer for consumption and also make the resulting paper product easier to recycle or compost, as they contain fewer heavy metals and volatile organic compounds (VOCs).

Functional Printing for Freshness

The future of printing on food wraps involves more than just aesthetics. Functional printing allows for the incorporation of features directly onto the wrap material.

- Time-Temperature Indicators (TTIs): Small printed labels that change color based on the time and temperature history of the food. This allows consumers and retailers to quickly assess freshness and safety.

- Antimicrobial Agents: Researchers are developing methods to print natural antimicrobial compounds , like essential oils or silver nanoparticles, directly onto the wrap surface. These agents can actively inhibit the growth of bacteria and fungi, significantly extending the shelf life of the sandwich inside. This innovation in Printed Sandwich Wrap moves the packaging from a passive barrier to an active preservation tool .

The Circular Economy and the Future of Food Wrapping

The ultimate goal for Printed Sandwich Wrap and all food packaging is a circular economy , where waste is eliminated. This means choosing materials that are easily returned to the biological cycle (composting) or the industrial cycle (recycling). By continuously innovating in material science and printing technology, the packaging industry is moving closer to a future where the convenience of a sandwich wrap doesn’t come at the expense of the planet.